How Materne North America Slashed Packaging Costs With Predictive Procurement

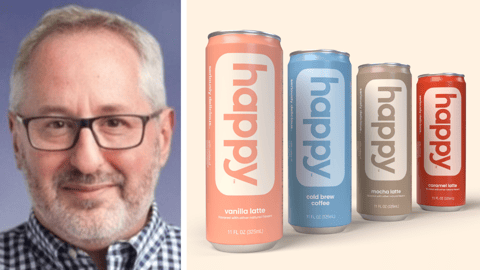

As many toddler parents will attest, fruit- and vegetable-filled pouches can act as a lifesaver product when it comes to slyly providing fussy kids with some much-needed vitamins.

Materne North America (also known as GoGo squeeZ) has become a major pouch player in the consumer goods industry thanks to this strategy. The company, which originated in France and expanded to the U.S. in 2008, realized it needed to reduce packaging spend and expand its carton supplier network after a period of double-digit growth, Mathieu Pappalardo, VP of procurement, tells CGT.

The CPG partnered with predictive procurement orchestration provider Arkestro to boost its supply chain resilience and slash costs — while simultaneously boosting compliance.

Squeezing Success From Spend

As a shelf-stable product, GoGo squeeZ experienced a sales growth spurt during the pandemic. As a result, Materne was looking for a solution that would save money and quickly identify pockets of potential profit.

“We had a lot of spend that company had that they had not touched,” Pappalardo explains. “We didn’t have the time, team, or resources to work on it. We were focusing on the big buckets, but there was a significant portion of spend that we were just ignoring.”

One issue was an over-dependence on spreadsheets and a lack of automation — a significant challenge when dealing with multiple RFPs across many smaller categories. Partnering with Arkestro in 2021 — initially as a pilot across a few categories — led to 30% savings where ordinarily, Pappalardo says, they’d be looking for around 5% in cost reductions.

Since then, Materne has focused on purchasing in the indirect category, achieving immediate savings and improved compliance. This shift in mindset put purchasing back at the center of things, increasing internal controls and driving a company-wide cultural change.

“Before, people wouldn’t necessarily think to come to [procurement] first. Now they do.”

Aiming for Continuous Cost Improvements

Extending use to the packaging space resulted in substantial savings: $1 million in packaging costs in a single event. The company also expanded its network, adding several new suppliers and increasing resilience.

While the partnership may not specifically address changing consumer preferences and expectations, Pappalardo says it's made the company stronger and more adaptable in its supply chain — always a plus when trying to meet demands.

The partnership has also improved the company’s ability to gather insights and the quality of data collected, incorporating suggested offers that automatically include correct product SKUs, resulting in less time cleaning up data for the procurement team.

In offering advice, Pappalardo recommends consumer goods companies regularly assess their supplier networks, identify areas of risk, and develop strategies for resilience wherever possible. For Materne, that means regularly re-identifying critical SKUs, reviewing, adding, or removing particular suppliers, and adapting procurement strategies to avoid disruptions.